|

Your current location:Home > Products > FERRITE MAGNET > Procedure Summaries

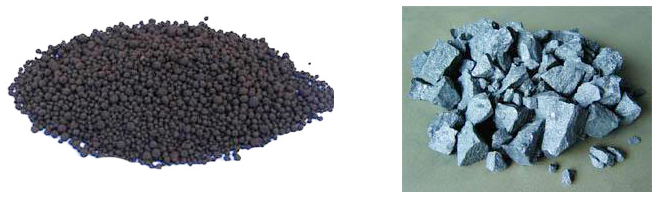

1.In case that the granular materials is purchased from our company, the particle should be dry ground to 3-5μm at first, and then be wet ground in a sand grinding mill or ball mill to less than 1μm, and then be wet pressed. If the coarse ground powder is bought, it can be wet ground directly. 2.All the necessary secondary additives have been added into the fine powders (<1μm). So there is no need to add any other material. But two to three hours' wet grinding is necessary for better distribution of particles. 3.During pressing, the moisture of slurry should be controlled between 32% to 37%. the pressure required is >4000/cm2, and the magnetic field density is >560 kA/m. 4.Due to the actual sintering temperature measured by various suppliers' instruments are not the same, we can only provide sintering temperature of 1220°C-1270°C for reference. Please note that the proper sintering temperature should be defined in accordance with the status of the sintered sample pill.

|